The Smarter Way to Build Fiber Networks, Via 3D & AI

Digital Twin Tech(DTT) is built to make power and fiber projects faster, smarter, and more transparent. It brings together a mobile 3D scanning app, AI-powered data processing, and a web-based digital twin—giving your team real-time visibility and control from the field to the office.

With DTT, you reduce delays, improve decision-making, and keep crews, managers, and clients aligned at every stage of the project.

Surveyors are no longer required for routine documentation. DTT’s as-built capture and 3D scanning tools let crews handle common field tasks themselves, freeing surveyors to focus on higher-value work while ensuring accurate, time-stamped project records.

Comply with regulations on secure data sharing, and field sensor data security.

________________________

Key Values

Cost Savings: Audit Amount Of Cable Used, Integrated To Payables, Save Millions Per Year

Cost Savings: Substantially Reduce Manual Work Of Field Teams To Dig & Locate Installed Fibre Cable Via Daily Uploads Of Manual Field Scans To Platform. Save Millions Per Year

Cost Savings: Substantially Reduce Or Eliminate Expense and Time Lost Of Field Surveyors, No Longer Needed, Save Millions Per Year

Regulatory Compliance: Comply With Regulatory Requirements Of This Type Of OT/IoT Sensor Data, and Secure Field Sensors

Data Security: Share This Information, Military Grade Security, Only With Appropriate Parties.

Future Roadmap: Integrate Network Degradation Into Platform – Environmental(Chemical, UV Radiation, Etc), Installation Errors(Via Bending, Splices, Connectors), Physical Damage(Construction, etc), Transceivers, and more

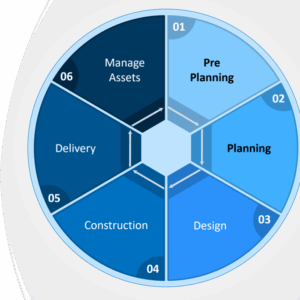

Single Digital AI Solution Across The Lifecycle

__________________

Secure Complete Solution With Customer Service Support

- ALL Current AND Historical Jobs & Locations On A Single Platform – Job Documents, Video, Images, 3D Models All Geo-Located

- Slice and Dice Information – By Type, Time/History, Real Time, Location and much more

- Embedded Artificial Intelligence (AI), Where It Creates Value

- Military Grade Data Security To Share With Contractors and Sub Contractors, For Maximum Efficiency And Minimize Errors

- Optional Capability: Continuous Monitoring Of Fibre For Hot Taps, Prevent Accidental Construction Cuts, Degradation, Sabotage, and more

- On Computer, Mobile Tablet, Virtual Realty, Augmented Reality and much more

- Client Does NOT Need To Hire IT Staff, Technology Systems, Servers, Field Hardware and More

- This information(locations, dates/time, documentation, 3D models, video, images, etc) is available and collaborative for teams, for the next 100 years, creating decades of substantial efficiency to manage the network.

- Customer Support and Quarterly Reviews To Assure Savings And Values Sought Are Measured, Achieved And Displayed Within DTT Platform To Client Every Day

__________________

Pre-Planning Work

- Pre-Plan Where Work Is To Be Performed

- Send to Field Teams and Equipment

- Audit Work Performed

- Audit Variances Of Material Used

The Ultimate Jobsite Documentation Toolkit

- DTT empowers field crews to capture GIS data, perform redlines, and create internal as-builts directly on site, using intuitive, survey-grade tools. By enabling teams to handle routine documentation without waiting on surveyors, DTT streamlines workflows while maintaining accuracy and consistency across projects.

- With built-in 3D scanning, crews can generate detailed models of trenches, utilities, and installations in minutes. These can be instantly shared with designers or project teams, improving collaboration and speeding up decision-making.

- The result is a complete, time-stamped, and geo-referenced record—ideal for fast-paced delivery and long-term asset management. Less rework, fewer delays, and total confidence in your field data.

[click bottom right corner for full screen and un-mute]

__________________

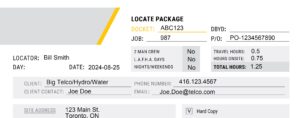

Document, Audit & Locate Work

Capture installed quantities directly at the source through a crew-friendly mobile app. Each entry is tied to its exact location, with photos, annotations, and timestamps for context. This field-focused approach keeps production visible day-to-day, rather than learning about progress weeks later from spreadsheets.

With real-time progress updates against your plan and automatic roll-ups into pay items, you always know exactly where you stand. Plus, every quantity comes with inspection-ready documentation as proof of work.

Crew-Friendly Mobile Capture: Log installed quantities directly in the field with simple mobile entry—no paper, no spreadsheets. Each entry is geotagged, timestamped, and tied to photos and redlines for full context.

Real-Time Progress Visibility: Track production against plan daily, not weeks later. Project managers and office staff get instant updates for better decisions, faster adjustments, and tighter job control.

Pay Item Rollups & Audit-Ready Proof: Quantities automatically roll up to pay items, complete with inspection-ready documentation. Eliminate disputes and accelerate approvals with data that’s always field-verified.

Protect Your Margins: Catch overruns early and course-correct before they impact cost. DTT’s real-time tracking helps you minimize waste, reduce rework, and improve profitability across every job.

[Click on image below for sample locate report]

__________________

Functional Highlights

Survey-Grade Accuracy: Capture data with pole-based GNSS or DTT’s AR-powered workflows, achieving cm-level accuracy. Whether collecting from the ground or viewing in AR, DTT delivers field-ready accuracy without complex setup.

Structured GIS or Quick Redlines: DTT supports both formal GIS data capture and quick, sketch-style redlines. All inputs are geo-tagged and accurate to within cm for consistent, reliable results.

Instant Accuracy Validation: Collect high-quality data with confidence. Using AR overlays, DTT instantly confirms accuracy in the field, enabling non-specialists to document utilities, site conditions, and redlines.

Add 3D Scans to Any Data Point: Augment any record with a 3D scan captured in seconds with iPhone or iPad. Use DTT’s built-in AI to automatically process and extract features.

__________________

Simple, Smart, and Built for the Field

With DTT, quantity tracking isn’t just accurate—it’s effortless. The process is integrated directly into redlining, so crews capture quantities as they mark up drawings, eliminating redundant steps and reducing time spent measuring in the field. DTT’s AI assists by interpreting inputs, streamlining data entry, and ensuring each item is geotagged, timestamped, and tied to the right pay item or asset.

The result is faster, cleaner tracking with less friction for the crew and more reliability for the office. You get a real-time picture of what’s been installed without extra paperwork or added survey work so you can stay ahead of schedule and on top of costs.

____________________________________

Extremely Fast Location of Buried Cable & Faults

- Quickly and Easily Locate Existing Cable

- Very Simple User Training, For Rugged Field Workers

- Integrated To Web Platform Via Daily Uploads – Field Data Uploaded To Platform, Locations Logged, Date Stamped

- Plug In A-Frame Fault Locators To Pinpoint Cable Faults Caused By Rodents, The Shifting Earth Or A Ground Probe Bar Being Driven Into The Soil And More.

- Lat, Long and Depth Accurately Recorded, CM Accuracy

- Locate Cable At Angles, Under Ground And Around Obstacles

___________________________________________

Locate Faults Quickly, No Digging

- Depth of cover reading to cable

- Lightweight 4.2lbs/1.89kg design

- Fully automatic operation

- Audible Left/Right cable path locate function

- Detect up to 2 Mohm ground faults

- Discriminates between light and heavy faults

- Simultaneously locate both cable and fault

- Forward/Back directional arrows point to the faults

[click bottom right corner for full screen and un-mute]

__________________

Collaborate And Integrate

- Collaborate Field, Office Teams & Systems

- Everyone Is On The “Same Page”

- Integrate To Work Order, Asset Management Systems And More

COMMUNICATION & COLLABORATION

Owner Staff, Prime and Sub contractors all use same verified information to save time and reduce errors.

FORCE MULTIPLIER & STAFF SAFETY

Augment inspection and allow staff to view remotely, away from potentially hazardous inspection processes. Objective, AI asset status, represents a force multiplier to staff expertise especially in times of COVID.

DIGITAL TWIN SPANS TIME

See the Past, View Present(Real Time), Predict Future

VALUES AGREED UPON, ARE VALUES DELIVERED BY Digital Twin Tech

Digital Twin Tech and Client agree upon baseline values to be created(dollars saved, safety, speed, etc). Digital Twin Tech provides report card each quarter on results to support continual improvement above baseline.

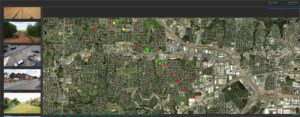

Historic Data Integration

Images & Work Orders

_______________________________________________

Geo Locate Historical Projects On To Platform

- Provide Images

- Provide Associated Work Orders

- Automated AI Analytics To Geo Locate Images and Work Orders To Platform, With Dates

- Slice & Dice: Searchable, By Date, Type Of Job, and More With All Other Field Data

What is Lorem Ipsum?

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Lorem Ipsum

- Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s